Extracting sulfur from crude oil before use is preferred for environments worldwide because of the harm that sulfur emissions can cause. But as people use millions of gallons of oil every day and oil companies’ reservoirs of this bright yellow substance continue to grow, it begs the question of what good can sulfur be used for?

Jeffrey Pyun, a professor in the University of Arizona’s Department of Chemistry and Biochemistry, and Kyung-Seok Kang, a postdoctoral research associate in the same department, have been working on developing a plastic that can help remove tons of sulfur buildup in oil companies around the globe.

A presentation done by Pyun described that the U.S. alone goes through 18.19 million barrels of oil each day, with 1 to 5% of each barrel being sulfur content that must be filtered out. Companies cannot simply allow the oil to be burned without filtering out the sulfur because of the way it reacts with oxygen in the atmosphere.

If sulfur is released as a byproduct of burning fossil fuels, it can react with oxygen to create sulfur oxides, which are pollutants that can cause major issues environmentally as they contribute to the formation of acidic rain.

Thanks to advancements in chemical engineering, Pyun went on further to say that elemental sulfur can be filtered out of oil without much issue, however, this leads to tons of sulfur build-up.

RELATED: Footprints suggest humans arrived in the Americas earlier than previously thought

“The problem is we have so much sulfur now … about 70 million tons annually. … And there is not much we can use it for, really just a few commodity-based chemicals and we don’t have many applications or chemical products. [They] get about 6 to 7 million tons of excess and they make these enormous towers of sulfur,” Pyun said.

From this, it was apparent to Pyun and his research group that these stockpiles of sulfur could lead to a business venture.

“We said, ‘Jeez it would be great if we could actually make plastics from this,’ and this was a great opportunity for us to engage the oil industry because they have so much sulfur, they just don’t know what to do with it,” Pyun explained.

In 2010, Pyun and his group created the notion of building plastics from sulfur and started working on this project in 2017 after getting sponsored by an Italian oil company called Eni.

Kang is one of the people Pyun employed to help achieve this mission.

RELATED: UA researches using swarms of robots to mine on moon’s surface

Not originally from the United States, Kang studied nanoscience and engineering for his undergraduate degree and eventually focused on polymer science in his doctoral studies at Pusan National University in South Korea. This happened to be one of the universities that Pyun teaches at during the summertime and where he looks for talented individuals who could be assets to his work. Kang left his home and family to pursue polymer sciences after Pyun recruited him to work on this project.

Of course, this goal of using waste sulfur as a cheap way to create plastics comes with its challenges. First, Pyun, Kang and the rest of their team had to establish whether their sulfur-based plastic would be comparable to the regular hydrocarbon polymers. Then, they wanted to see if their creation could be competitive in the plastic industry by having properties other plastics did not.

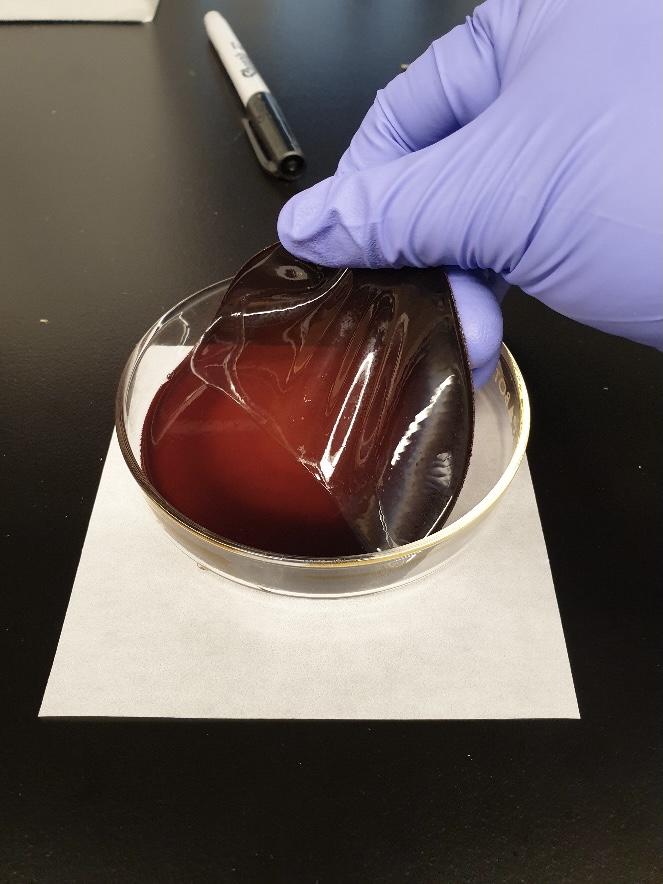

While their work is still in progress, under the leadership of Pyun, Kang and his team have been able to develop a plastic that is both elastic and flame retardant from sulfur. The elasticity of the plastic helps it to compete with the many other non-brittle plastics available, and it being flame retardant was a surprise that Pyun and Kang both said they hope can give it an edge.

“I decided to work on polymer sciences because I enjoy making something entirely new, and here we have found an entirely new property, [the flame retardancy],” Kang said.

Follow Trinity Clark on Twitter